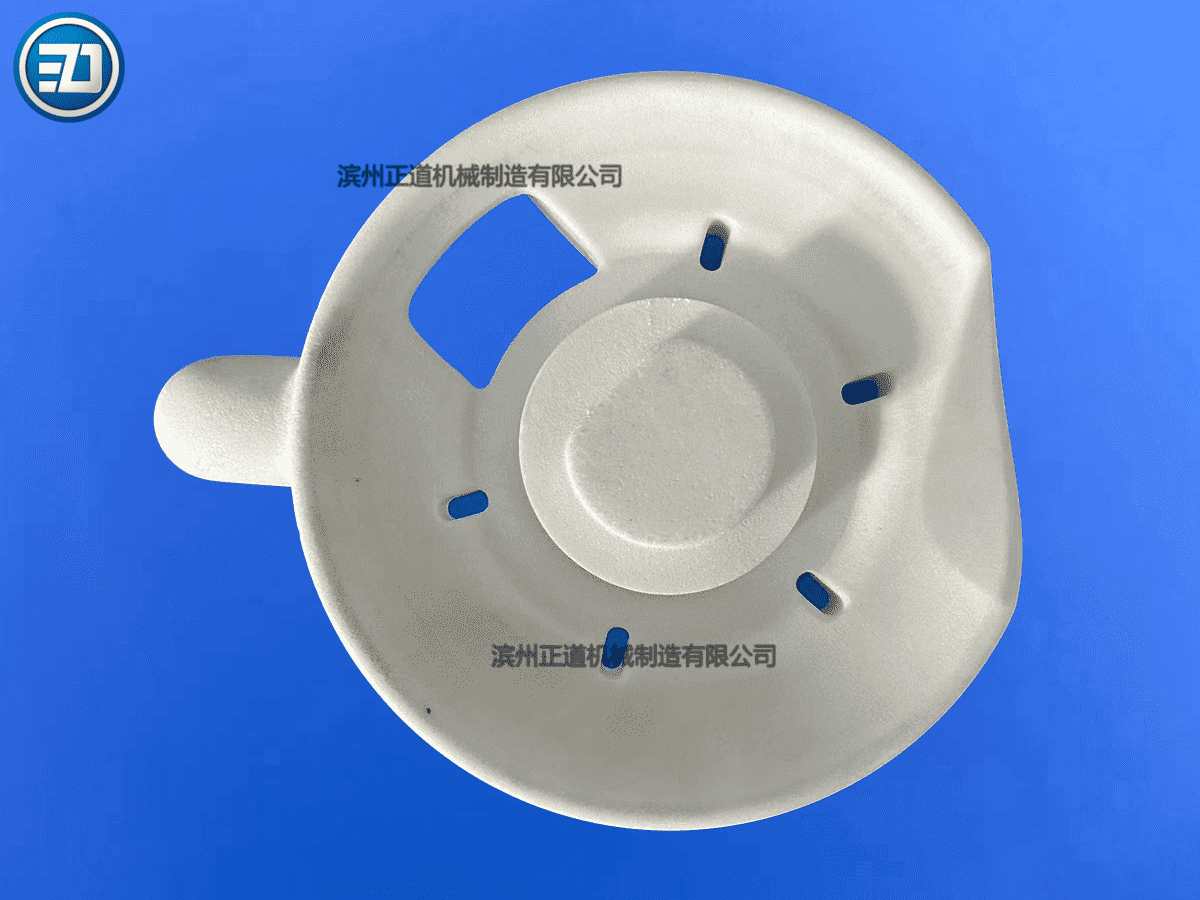

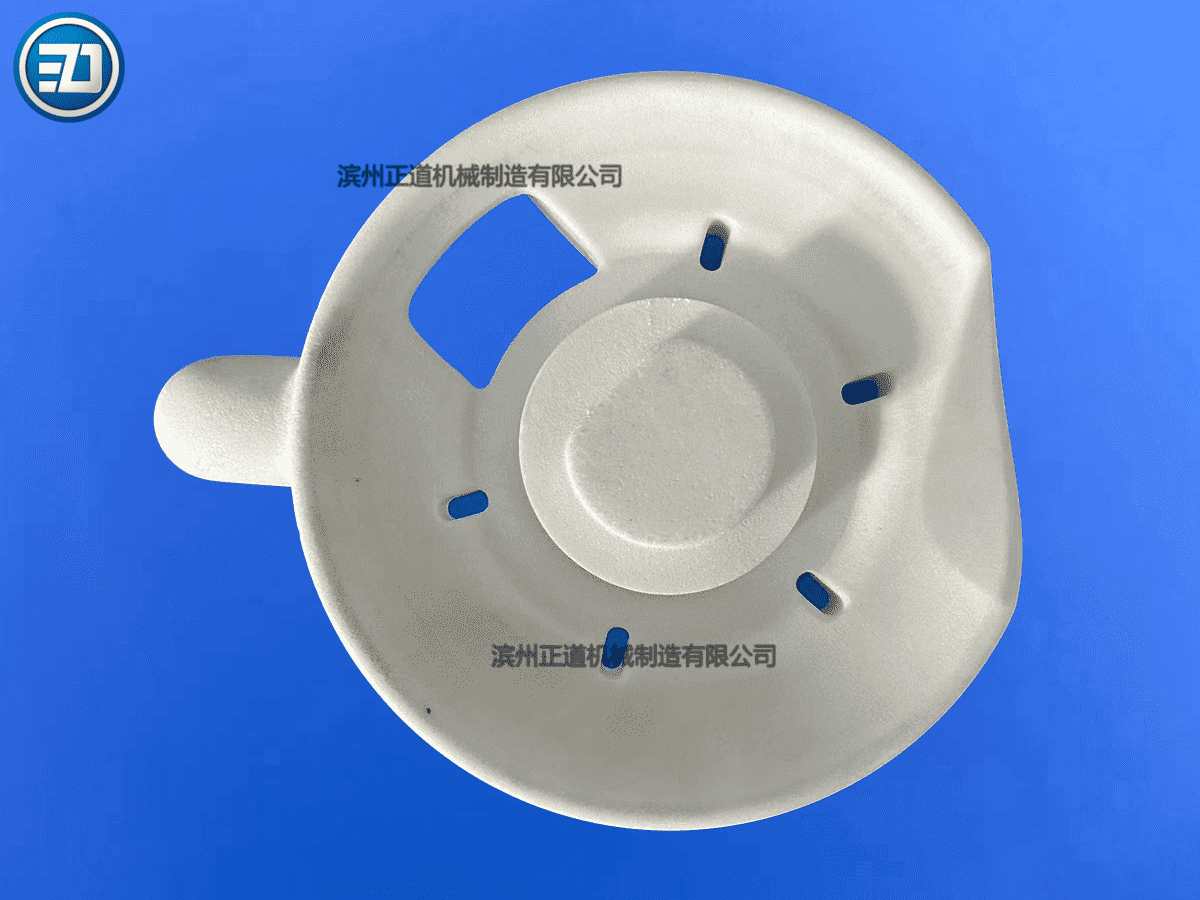

Forming of complex and narrow internal cavities in aluminum-magnesium castings.

Forming of complex and narrow internal cavities in aluminum-magnesium castings.

1.Compared to the ring-shaped piston salt cores, irregular-shaped salt cores can be produced in any desired form through optimized and upgraded manufacturing processes.

2.The strength of irregular-shaped salt core is higher than the normal piston salt core.

3.Compared with sand core and ceramic core, salt core is easier to clean and has better surface finish.

4.It is mainly used for cavity and weight reduction part of lightweight aluminum magnesium castings.

5.Non-toxic, odourless and water soluble: salt core can be rinsed easily with water after casting without any residue.

(1) New salt cores can be used for forming internal cavities of lightweight aluminum-magnesium castings.

Advantage: The use of salt core in the piston field has been a very mature process, the new salt core is developed by Zhengdao on the technical extension line of piston salt core. The emergence of new type of salt core can easily solve industry problems such as high porosity, sand sticking and difficult sand cleaning in sand castings. Good surface finish of the salt core is beneficial for fast punching. Salt dissolves in water and can be flushed with pressure water to achieve no residue.

Most lightweight aluminium magnesium castings are currently molded with resin sand core. The large amount of air generated from the sand core affects the quality of casting. Sticking sand must be solved by adding processing procedures, and there is a problem that cannot be removed.

(2) The new type of salt core can be applied to the molding of the parts of injection molding products that cannot be processed and are difficult to be processed.

Advantage: The emergence of new type of salt core provides solutions for customers to manufacture complex and narrow cavity products, and achieve the effect of less or no processing, improving the production efficiency.